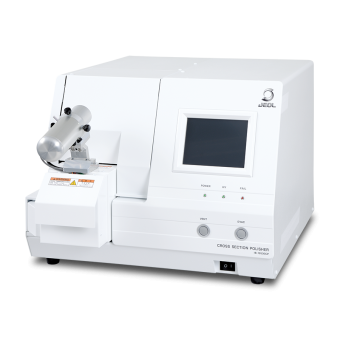

IB-19520CCP CROSS SECTION POLISHER™

IB-19520CCP CROSS SECTION POLISHER™

-

IB-19520CCP

-

JEOL

-

Japan

- Danh mục:

-

116

Thermal damage can be reduced by cooling the specimen with liquid nitrogen during processing.

Designed to suppress the consumption of liquid nitrogen, allowing long cooling periods.

Rapid cooling of the specimen while immersed in liquid nitrogen. Return to room temperature. Designed to allow parts to be detached.

Incorporates a mechanism to allow the process from polishing to observation to be performed without exposing the sample to the air.

- Giới thiệu

- Thông số kỹ thuật

- Ứng dụng và tiêu chuẩn

- video

- Tài liệu

Features of IB-19520CCP

Cooling effect

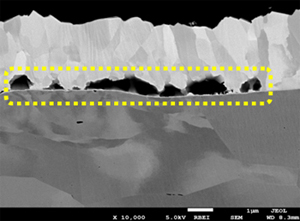

Specimen: Galvanized iron steel

Normal milling (without cooling) Cooled milling (holder temperature -120°C)

Accelerating voltage 4kV Accelerating voltage 4kV

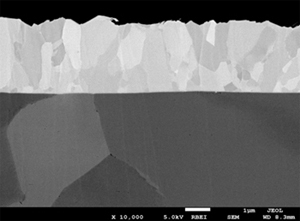

Intermittent process, Cooling and Cooling with temperature control functions handle a variety of work pieces

Process monitor function

The status of the cross-section milling can be monitored in real-time with the CCD camera.

And the magnification can be varied.

Cross Section Preparation kit

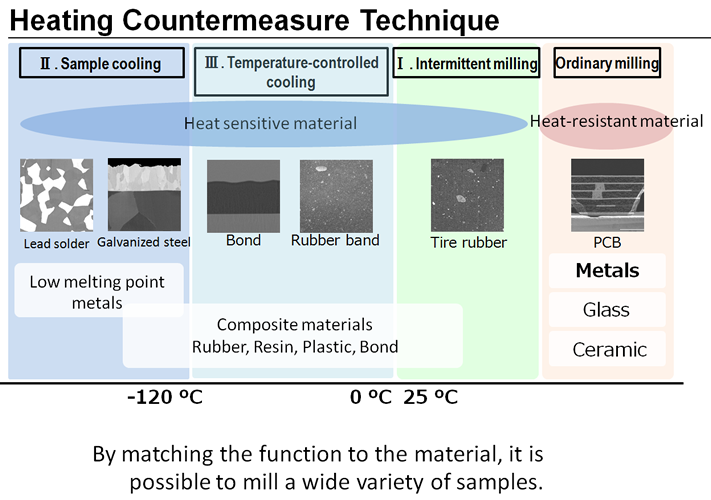

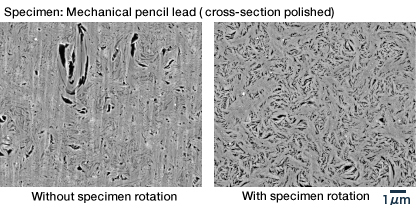

This is a kit for performing ion beam milling while rotating the sample.

This kit is used with the Planar ion milling holder.

Makes it possible to create cross-sections of samples prone to streaking when milled, such as porous materials, powders and fibers.

| Ion accelerating voltage | 2 to 8kV |

|---|---|

| Ion beam width | 500 μm (full width at half maximum) |

| Milling speed | 500 μm/h (The average value over 2 hours, at accelerating voltage: 8 kV, specimen: Si, 100 μm from edge) |

| Specimen holder ultimate cooling temperature | -120°C or less |

| Specimen cooling hold time | 8 Hours or more |

| Coolant tank capacity | Approximately 1 L |

| Maximum specimen size | Dimensions: 11mm(W)×8mm(D)×3mm(H) |

| Stage movement range | X-axis;±6mm, Y-axis; ±2.5mm |

| Specimen fixing method | Clipping |

| Specimen milling swing angle | ±30°(Patent US4557130) |

| Monitoring camera magnification | Approximately ×20 to 100 (6.5-inch display) |

| Air-isolation system | Transfer vessel |

| Air-isolation method | Set the inside of the chamber to a gas environment, cover the transfer vessel with a cap, and encapsulate the specimen into the vessel. |

| Operation | Touch panel, 6.5-inch display |

| Gas | Argon gas (flow rate controlled by mass-flow controller) |

| Pressure gauge | Penning vacuum gauge |

| Main evacuation pump | Turbo molecular pump |

| Auxiliary evacuation pump | Rotary pump |

| Dimensions and Masses | Main unit: Approx. 670mm (W) × 720mm (D) × 530mm (H) , Approx. 73㎏ Rotary pump: Approx. 120mm(W) × 288.5mm(D) × 163mm(H), Approx. 9.3㎏ |

| Option | Large Specimen Rotation Holder (IB‐11550LSRH) Mounting Base Specimen Holder(IB‐11560MBSH) Large Specimen Holder(IB-11570LSH) Carbon Coating Holder(IB-12510CCH) |

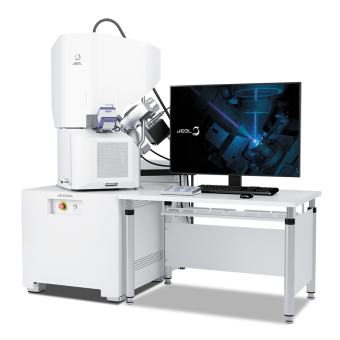

Sản phẩm cùng loại

Đọc thêm

Đọc thêm

Trụ sở: 19 Hàng Thiếc, P. Hàng Gai, Q. Hoàn Kiếm, TP. Hà Nội

Trụ sở: 19 Hàng Thiếc, P. Hàng Gai, Q. Hoàn Kiếm, TP. Hà Nội Email: sales@tnic.com.vn/sale1@tnic.com.vn

Email: sales@tnic.com.vn/sale1@tnic.com.vn Hotline: HCM: 0905 653 866 | HN: 0982 028 728

Hotline: HCM: 0905 653 866 | HN: 0982 028 728 Website: tnic.com.vn

Website: tnic.com.vn