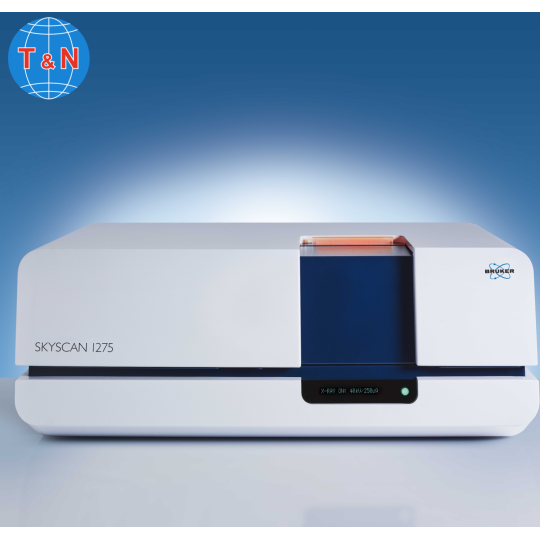

Skyscan 1275

Skyscan 1275

-

Skyscan 1275

-

BRUKER AXS

-

Đức

- Danh mục:

-

2131

- Giới thiệu

- Thông số kỹ thuật

- Ứng dụng và tiêu chuẩn

- video

- Tài liệu

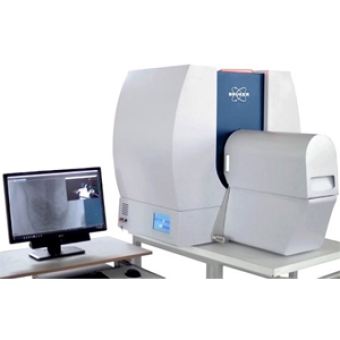

Just insert a sample, manually or automatically, and get a complete 3D volume without any further interaction.

Push-Button XRM includes everything: automatic sample size detection, sample scanning, 3D reconstruction, and 3D volume rendering. Ideal for routine tasks, or operation by non-expert users!

You need full control? No problem, SKYSCAN 1275 offers all features.

Combined with a sample changer SKYSCAN 1275 even works 24/7.

SKYSCAN 1275 Specifications

|

Feature |

Specification |

Benefit |

|

X-ray source |

20 – 100 kV 10 W < 5 µm spot size at 4 W |

Maintenance-free sealed X-ray source Fast scans for QC, or 4D XRM |

|

X-ray detector |

Active pixel CMOS flat-panel 3 MP (1944 x 1536) 75 µm pixel size |

Excellent signal-to-noise Large Field-of-View |

|

Object size |

96 mm diameter 120 mm height |

Capable to scan a large range of sample sizes |

|

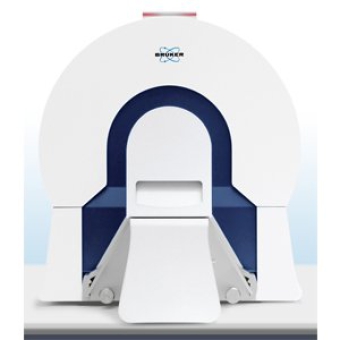

Sample changer (optional) |

16 samples up to 50 mm diameter 8 samples up to 96 mm diameter External access |

Unattended high throughput Any combination of large and small samples Add/remove samples at any time without interrupting the actual scan |

|

Dimensions |

W 1040 mm x D 665 mm x H 400 mm Weight 170 kg |

Space-saving desktop system that fits in every lab |

|

Power supply |

100-240V AC, 50-60Hz, 3A max. |

Minimum installation requirements, a standard power supply suffices |

Additive manufacturing, also commonly called 3D printing, allows the creation of components with complex external and internal structure. Unlike classic techniques which require special molding or tooling, additive manufacturing allows the economical production of both one piece prototypes and large batch production parts. Once completed, confirmation of both the internal and exterior structure is important in ensuring that the component will perform as intended. XRM allows this inspection in a non-destructive manner, giving confidence that a component will meet or exceed specifications.

- Inspection of internal voids for trapped powder

- Validation of external and internal dimensions

- Direct comparison with CAD models

- Analysis of single and multi-material components

Đọc thêm

Đọc thêm

Trụ sở: 19 Hàng Thiếc, P. Hàng Gai, Q. Hoàn Kiếm, TP. Hà Nội

Trụ sở: 19 Hàng Thiếc, P. Hàng Gai, Q. Hoàn Kiếm, TP. Hà Nội Email: sales@tnic.com.vn/sale1@tnic.com.vn

Email: sales@tnic.com.vn/sale1@tnic.com.vn Hotline: HCM: 0905 653 866 | HN: 0982 028 728

Hotline: HCM: 0905 653 866 | HN: 0982 028 728 Sale 1:

Sale 1:  Website: tnic.com.vn

Website: tnic.com.vn